metal shearing machine hazards

Wear proper clothing and PPE. Before use carefully check whether all parts are normal and whether the fasteners are firm.

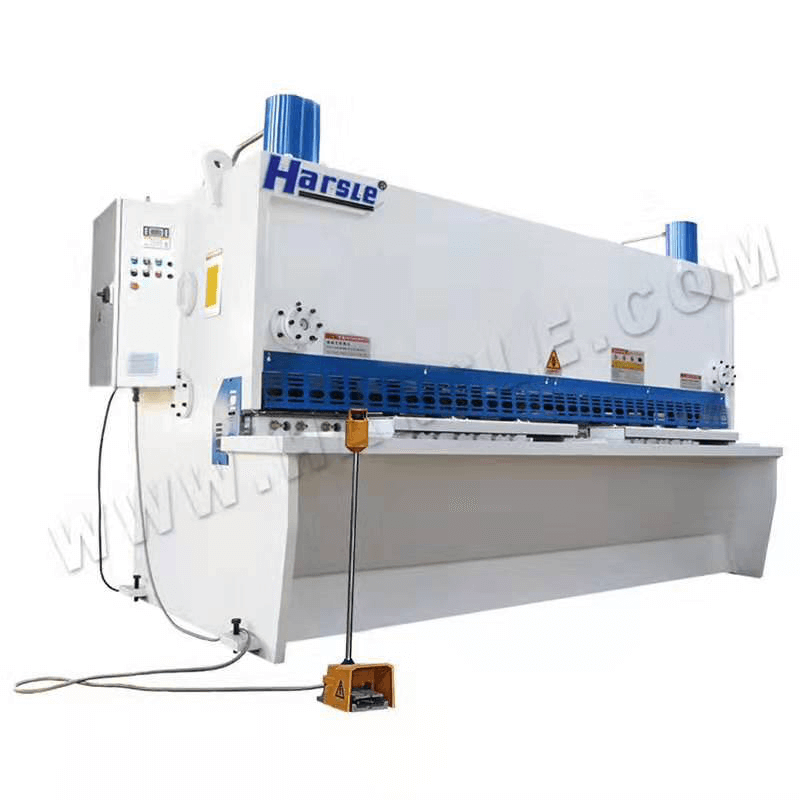

Shearing Machine Skills Training Harsle Machine

Workers must place their hands on the handle of the tool.

. Stressful hand and wrist activity may be forceful repetitive or characterized by extreme postures. The machine is a piece of powerful equipment that uses. Make sure everyone knows the right positioning to use when handling metal shears.

Determine what materials are used with the machine eg sheet metal wood metalworking fluid oil etc. Workers who operate laser cutter and metal shearing machine may face hazards from lifting and carrying manual materials handling. Using a Foot Operated Sheet Metal Shear Potential Hazards.

Keep the machine in shape. Shear or Cutting Point Safety Precautions. Introduction Operation Steps And How To Solve The Problem Of The Large Sheet Metal Bending Machine Primapress Clean the Tool Regularly.

Determine at least one control strategy from each level of the hierarchy of controls elimination substitution engineering. People will get injured quickly if their hands are near the blade. Flat Sheets only up to 116 15mm.

Working with and fabricating metal sheets is a job that requires the assistance of a shearing machine. While the process can result in defects these can be avoided provided that you follow these recommended methods. Never use the shear for cutting metal that is beyond the machines capacity with respect to thickness shape hardness or type.

Punch and shear machines. While this guidance has not been updated to reflect current work health and safety legislation the Health and Safety at Work Act 2015 and regulations it may still contain relevant information and practices to keep. Turn the lights up.

Make certain any available safety enhancements such as light curtains or rear-guards are in place. Keep away from cutting parts. Proper placement will reduce the likelihood of.

While Operating the Sheet Metal Shearing Machine. Know your machine each shearing machine model will have different designs functions and shearing ability. Next our scrap metal shears suppliers will introduce to you the safe operating procedures for scrap metal shears.

Assure all covers and protective shields for equipment and machinery shear or cutting point hazards are in place. Always keep a lookout for overheating or smoking. Needs Grading Your organization recently purchased a large metal shearing machine.

Lifting heavy materials during the operation of a laser cutter and metal shearing machine can cause injury to muscles nerves discs and ligaments of the low back. EmployeeS Finger Is Caught In Shear Hold Down And Is Amputa. Article 108-2 of Ordinance Take measures to prevent the body parts of workers from entering the hazardous area.

Shearing machines work with sharp cutting parts and you can bet that machines that can cut metal can easily cut through skin and bone. If the machine stops functioning ensure the power supply is turned completely off. Employee Sustains Finger Amputation From Metal Shear.

Another hazard associated with operating machine cutting shear is the slips falls and trips which may make the hands to be trapped cuts and bruising. The cut will also be uneven if the users hands arent at the base where they should be. Sheet Metal Shearing Tool Safety Tips.

Check that the oil in the oil storage tank of the shearing machine should be sufficient. For powered shears turn on the shear and operate it through a test cycle to verify functionality. After starting the oil pump check the valves.

Cutting points occur when a single object moves forcefully or. Estimate the risk of each hazard by considering the. Performing stressful hand activities while operating laser cutter and metal shearing machine can lead to tendon inflammation tendonitis in the hand wrist or elbow or carpal tunnel syndrome.

These machines can perform a number of functions including shearing punching notching or bending. Roll-Bending Machines 34 Hazards of Shearing Machines 35 Safeguarding Shearing Machines 36 Other Controls for Shearing Machines 36 Hazards of Food Slicers 37. You have been asked to identify the hazards of operating this equipment and make.

Insert workpiece into the shear align with the side table guide and slide the workpiece until the cut line is aligned with the shear blade. Turn it off properly after using. In a typical shear point hazard one part moves while the other part is either stationary or moving.

Roll-Bending Machines 34 Hazards of Shearing Machines 35 Safeguarding Shearing Machines 36 Other Controls for Shearing Machines 36 Hazards of Food Slicers 37. Check all covers and safety enhancements. The shearing process is needed in metal fabrication to achieve clean cuts and straight-edged custom pieces.

Belt Conveyor 27 Figure 28. Roll-Bending Machines 34 Hazards of Shearing Machines 35 Safeguarding Shearing Machines 36 Other Controls for Shearing Machines 36 Hazards of. Inspect the tool and the surroundings for hazards equipment damage or missing guards.

Place and maintain warning labels adjacent to shear or cutting point hazards. Take necessary safety measures to prevent possible hazards caused by the shearing machineArticle 20 of Act When there is a risk that the stroke end of the machine may endanger workers take safety measures to prevent hazards. You have been asked to identify the hazards of operating this equipment and make recommendations of ways to control the hazards.

A shear point hazard exists when the edges of two machine parts move across each other or move closely enough together to cut another object or move a relatively soft material. Exposed blade with significant mechanical advantage when handle is pulled. Employee Amputates Finger While Feeding Metal Stock Into.

Two-Person Power Press Brake Operation with Pullbacks 26 Figure 27. Turn the power off immediately if this occurs. Non-specific low back pain is.

Wear snug clothing remove jewelry and tie long hair back or secure under a cap before working in the vicinity of shear or cutting point hazards. Power Press Brake Bending Metal 25 Figure 26. Employee Attempts To Clear Jam In Shear Machine And Receives.

Identify shearing hazards where a worker could be severely cut by being between two machine parts or between a machine part and a workpiece or stationary object. Employee Sustains Finger Amputation From Metal Shear.

Safe Operation Of Sheet Metal Guillotine Shear Useful Tips 2022

Century Plate Shear Machine Safety Tips Bwm Services Blog

Shear And Cutting Point Injuries Machineaccident Com

Safe Operation Of Sheet Metal Guillotine Shear Useful Tips 2022

The Precaution Of Sheet Metal Shearing Machine Blma

Essential Safety Guidelines And Tips While Working With Sheet Metal Woodwardfab Blog

Safety Precautions Tips To Follow When Working With Sheet Metal Rolling Equipment Woodward Fab Blog

Safe Operation Regulations And Maintenance Of Hydraulic Shearing Machine Harsle Machine

High Uniformity Stable Cnc Steel With Hacmpress High Uniformity Steel Sheet Bending Machine Wc67k 100 2500 Im Press Brake Press Brake Tooling Cnc Press Brake

Shear And Punch Machine Safety Procedures Acra Machinery

Pin Op Cnc Plate Shearing Machine

Brand New Betenbender Hydraulic Shear Sterling Machinery Hydraulic Shear Safety Switch Hydraulic